FIG PUBLICATION NO. 25

models

and terminology for the analysis of geodetic monitoring observations

Official Report of the Ad-Hoc Committee of FIG Working

Group 6.1

Prof. Walter M. Welsch, Institute of Geodesy, Bundeswehr

University Munich, Germany

Prof. Otto Heunecke, Geodetic Institute, University of

Hannover, Germany

CONTENTS

PREFACE

ABSTRACT

1. HISTORY AND INTRODUCTION

2. CONCERN OF

DEFORMATION MEASUREMENTS

3. CONVENTIONAL

DEFORMATION ANALYSIS

3.1 Congruence Models

3.2 Kinematic Models

4. DYNAMIC SYSTEMS AND ADVANCED DEFORMATION

ANALYSIS - SYSTEMATIZATION OF DEFORMATION MODELS

5. SYSTEM IDENTIFICATION BY

PARAMETRIC AND NON-PARAMETRIC MODELS

5.1 Parametric models

5.2 Non-parametric models

6. SOME EXAMPLES OF APPLICATION

6.1 General Procedure

6.2 Example Using a Parametric Model

6.3 Non-parametric Input-Output Model of a Turbine Foundation

6.4 Integrated Parametric Analysis of Ground Subsidence

7. POTENTIALITY OF DYNAMIC MODELS

8. CONCLUSION

REFERENCES

Orders of the printed copies

It is my great pleasure, as the chairman of FIG Working Group 6.1

(Deformation Measurements), to introduce to the members of FIG this final

report of the ad hoc Committee on Terminology and Classification of

Deformation Models. I would like to thank Dr. Walter Welsch and Dr.

Otto Heunecke for undertaking the difficult task of summarizing the

results of 8 years of research and discussions (sometimes heated) on the

subject within the activity of WG 6.1. The need for the special study of the

classification and terminology used in deformation modeling was recognized

at the 6th International Symposium organized by the FIG WG 6.1 (formerly

known as WG6C) in Hanover, Germany, in 1992. The need arose as a result of

the growing interest in the interdisciplinary approach to physical

interpretation and modeling of the relationship between causative factors

(loads) and deformation. Though basics of the load-deformation analysis are

well known in applied physics and mechanics of deformable bodies, geodetic

engineers have entered the discipline only recently. At the symposium in

Hanover, some authors became confused with the use of the terms such as

dynamic or kinematic models of deformation, deterministic vs. statistical,

or parametric vs. non-parametric modeling, etc. Though this final report may

not satisfy all specialists in deformation modeling, who may be coming from

various fields of science and engineering, it gives geodetic engineers a

solid basis for a unification of terms used in deformation modeling.

Certainly, there will be still more discussion on the subject but the

background gained from this report will help geodetic engineers to better

understand the finesses of the modeling processes.

This report represents one of the latest involvements of Working Group

6.1.The group has always been one of the most vital groups of FIG Commission

6 and one of the most active international groups dealing with the problems

of monitoring and analysis of deformation surveys in engineering and

geoscience projects. Although the accuracy and sensitivity criteria for

determining deformations may considerably differ between various

applications, the basic principles of the design of monitoring schemes and

their analysis remain the same.

Due to the constantly growing technological progress in all fields of

engineering and, connected with it, the increasing demand for higher

accuracy, efficiency, and sophistication of the deformation measurements,

geodetic engineers have to continuously search for new monitoring techniques

and have to refine their methods of deformation analysis. Working Group 6.1

has played a very important role in providing a forum for the exchange of

information in the new developments by organising ad hoc study groups,

technical sessions during the FIG Congresses and, more important, by

organising specialised international symposia on deformation surveys. These

have occurred in 1975 in Krakow, Poland, in 1978 in Bonn, Germany, in 1982

in Budapest, Hungary, in 1985 in Katowice, Poland, in 1988 in Fredericton,

Canada, in 1992 in Hanover, Germany, in 1993 in Banff, Canada, in 1996 in

Hong Kong, in 1999 in Olsztyn, Poland, and (the 10th symposium) in Orange,

California, in 2001. The published proceedings of those symposia provide an

enormous wealth of information on the development of new techniques and new

methods in monitoring and analysis of deformations. The next symposium is

planned to be held in Greece in 2003.

Professor Adam Chrzanowski

Chairman, FIG Working Group 6.1 - Deformation Measurements

MODELS

AND TERMINOLOGY FOR THE ANALYSIS

OF GEODETIC MONITORING OBSERVATIONS

Official Report of the Ad-Hoc Committee of FIG Working

Group 6.1

Walter M. Welsch

Institute of Geodesy

Bundeswehr University Munich

D-85577 Neubiberg

Germany

Otto Heunecke

Geodetic Institute

University of Hannover

D-30167 Hannover

Germany

The paper in hand is the result of the studies of the Ad-Hoc Committee

'Classification of Deformation Models and Terminology' of Working Group 6.1

'Deformation Measurements', FIG Commission 6. The Ad-Hoc Committee was set

to work due to a recommendation of the chair-man of FIG-Working Group 6.1 on

the occasion of the 6th International FIG-Symposium on De-formation

Measurements in Hannover in 1992. Earlier reports were given on the 7th

International FIG-Symposium on Deformation Measurements in Banff, Canada in

1993, on the Perelmuter Workshop on Dynamic Deformation Models in Haifa,

Israel in 1994, and in 1996 at the 8th International FIG-Symposium on

Deformation Measurements in Hong Kong. A summary of the studies was

presented at the 9th FIG-Symposium on Deformation Measurements in Olsztyn,

Poland in 1999. The closing session of this symposium was devoted to a

comprehensive discussion on the topic. It was concluded by the chairman of

Working Group 6.1 summarizing the activities concerning the methods and

models of deformation analysis during the past two decades. The paper here

as submitted to the 10th FIG International Symposium on Deformation

Measurements in Orange, California in 2001 is the official final report of

the Ad-Hoc Committee and includes the proposals discussed in Olsztyn.

A summary of the studies can be described as follows: The deformation of

an object is the result of a process. The today's techniques offer the

possibilities to measure and analyze such a process in all details. This is

in accordance with the current trends in engineering surveying which intend

to determine not only the geometrical changes of an object in a

phenomenological manner but rather the dynamics of the process, i.e. the

investigations aim at incorporating the causative forces and the physical

properties of the body. In its entirety, the body, the causative forces and

the resulting deformations are considered a dynamic system. Consequently,

the most general and comprehensive models are dynamic models, from which -

by simplification - static, kinematic and congruence models are derived. The

simplified models offer the possibility of meeting many practical aspects of

deformation analysis which do not necessarily require the complete

investigation of the process in all details.

As a result it can be stated that in our days 'geodetic deformation

analysis' means 'geodetic analysis of dynamic processes'. The tools to do

so, are made available by disciplines like e.g. the sciences of civil

engineering, mechanics, filter and control engineering, signal analysis, and

system theory. Especially system theory provides an established terminology

and classification of models for an up-to-date deformation analysis in the

above sense and in accordance with the latest trends of engineering

surveying. Deformation analysis should be considered an interdisciplinary

concern to the benefit of all sciences involved.

In the late 1970s and early 1980s, Working Group 6.1 of FIG concentrated

their efforts on the development of new monitoring techniques and on the

geometrical analysis of frequently ob-served geodetic deformation networks,

continuous measuring techniques were just at the beginning. This state is

reflected e.g. in the content of the papers presented at the 1st

FIG-Symposium on Deformation Measurements in Krakow (1975). At that time,

the main problem of the deformation analysis was the identification of

unstable reference points in geodetic monitoring networks. Several

approaches were proposed by different authors. As a result, an Ad-Hoc

Committee on Deformation Analysis was established at the 2nd Symposium in

Bonn (1978) with the task of comparing different approaches and developing a

unified theory for the geometrical analysis of deformation surveys. Several

research centers joined the work of the committee, with the most active

centers being from universities of Karlsruhe, Hannover, Stuttgart, and

Munich in Germany, universities of New Brunswick in Canada, and Delft in the

Netherlands. The work of the Committee was summarized at the XVI.

FIG-Congress in Montreux (Chrzanowski et al. 1981), at the 3rd Symposium on

Deformation Measurements in Budapest (Heck et al. 1982), at the XVII.

FIG-Congress in Sofia (Chrzanowski and Secord 1983), and at the XVIII.

FIG-Congress in Toronto (Chrzanowski and Chen 1986).

Parallel to the work of the Ad-Hoc Committee on Deformation Analysis,

several researchers especially at the universities in Stuttgart

(Felgendreher 1981, 1982), Hannover (Boljen 1983, 1984), in Fredericton

(Chrzanowski et al. 1982; Chen 1983; Chrzanowski et al. 1986; Chen and

Chrzanowski 1986), in Calgary (Teskey 1986, 1988), and in Munich (Ellmer

1987; Kersting 1992) initiated work on expanding the deformation analysis

into the physical interpretation and modeling of the relationship between

causative factors (loads) and the resulting deformations. Some authors began

already to take advantage of the increasing importance of automated

measuring techniques (e.g. Pelzer 1977a, 1977b, 1978). The work of these

researchers was fundamental for the development of geodetic deformation

analysis to a deeper and wider understanding of deformation phenomena which

are basically the result of dynamic processes. It was understood that

deformation analysis has basically to be seen from an interdisciplinary

point of view. Consequently the field of geodetic deformation analysis

expanded, e.g. into civil engineering and geotechnical applications.

The more geodesists and engineering surveyors went into the analysis of

dynamic processes, the more confusing were the technical terms they were

applying to their studies. The terminology which could have been used was

well established in physics and mechanics and in other sciences a long time

before geodetic engineers became involved in the physical interpretation of

deformation. In 1992, at the 6th FIG-Symposium in Hannover, some papers made

the confusion obvious: e.g. the purely geometrical analysis of deformation

measurements was called 'static' by some authors, or the time dependent

geometrical analysis was named 'dynamic', particularly when dealing with

cyclically changeable deformations etc. The main confusion arose from the

fact that it was not distinguished between modeling the geometrical

(descriptive) comparison and the load-deformation relationship of the

observed deformation. Thus, as a result (Chrzanowski 1992) an-other Ad-Hoc

Committee was created in Hannover to look into the terminology and

classification of deformation models with a focus on dynamic models.

The original Ad-Hoc Committee consisted of professors Milev (Bulgaria),

Pfeufer (Germany), Proszynski (Poland), Steinberg (Israel), Teskey (Canada),

and Welsch (Germany). They presented two progress reports (Ad-Hoc Committee

1993, 1994) at the 7th FIG-Symposium in Banff in 1993 and at the Perelmuter

Workshop on Dynamic Deformation Models in Haifa in 1994. After that, some

members of the committee lost their interest in the work of the committee

and the commit-tee disintegrated. Nevertheless, Welsch (1996) gave a status

report on the proposed terminology at the 8th FIG symposium in Hong Kong

taking into account the latest trends and developments from system theory

and signal processing (e.g. Heunecke 1995). A summary of the ongoing studies

was then presented at the 9th FIG-Symposium on Deformation Measurements in

Olsztyn, Poland (Welsch and Heunecke 1999). The closing session of this

symposium was devoted to a comprehensive discussion on the topic. It was

concluded by the chairman of Working Group 6.1 summarizing the activities

concerning the methods and models of deformation analysis during the past

two decades (Chrzanowski 1999).

The following paper as submitted to the 10th FIG International Symposium

on Deformation Measurements in Orange, California in 2001 is the official

final report of the Ad-Hoc Committee and includes the proposals discussed in

Olsztyn. Some examples of practical applications illustrate the state of the

art of geodetic deformation analysis. They make obvious how the various

disciplines involved can derive benefits from the interdisciplinary aspects

of deformation analysis.

Summarizing, it can be said, that the traditional task of deformation

measurements has been the investigation of movements and displacements of an

object with respect to space and time. Driven by the development of

measuring and analysis techniques and the need of interdisciplinary

approaches for solutions, the goal of geodetic deformation analysis is

nowadays to proceed from a merely phenomenological description of the

deformations of an object to the analysis of the process which caused the

deformations, i.e. to incorporate the causative forces and the physical

properties of the body under investigation. In its entirety, the body, the

influencing forces and the resulting deformations are considered a dynamic

system. Thus 'Geodetic Deformation Analysis' means 'Geodetic Analysis of

Dynamic Processes' with the consequence that engineering surveying has to

understand to a certain degree the dynamics of the processes the object

monitored is involved in. Consequently, the most general and comprehensive

models are dynamic models, from which - by simplification - static,

kinematic and congruence models are derived. The simplified models offer the

possibility of meeting many practical aspects of deformation analysis which

do not necessarily require the complete investigation of the process in all

details. In many practical applications simply the graphical and numerical

representation of recorded geodetic measurements without any further

modeling is regarded as sufficient. Economic aspects of almost every

surveillance with respect to potential risks and hazards are essential,

extravagant expenses are generally avoided, and individual solutions with

appropriate models are usually requested.

However, the scenario is to be seen as a whole; each discipline has to

contribute its specific knowledge and expertise in quantifying and analyzing

the respective process. In any case, the surveying engineer is forced to

talk to his colleagues of neighboring disciplines like civil engineering,

mechanics, geotechniques, filter and control engineering, signal analysis

and system theory, to understand their technical language and thinking and

to make them acquainted with his own expertise and technical language.

Ideally the terminology applied should be standardized and be understood by

everyone involved. Hopefully, all disciplines involved will eventually speak

the same language. They have to interact and to complement each other,

albeit their specific measuring and analysis techniques may remain

different.

Before entering the discussion on models and terminology some brief

statements on the main tasks of deformation measurements are advisable.

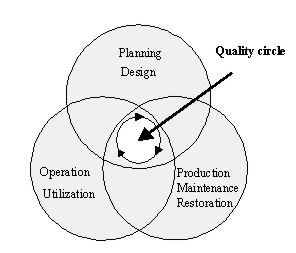

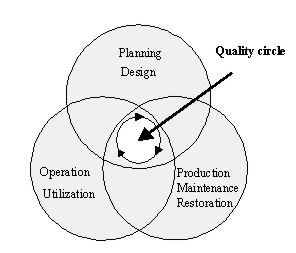

Engineering surveys are involved in all phases of the lifetime of a

construction (Fig. 1). With respect to this report, deformation measurements

during the operation and utilization phase are of special interest. The

essential task of deformation measurements and their analysis during this

phase is a comprehensive and pertinent description of the state of an object

under investigation. Other geodetic contributions to the quality circle will

not be discussed. An explicit distinction between man-made structures and

natural objects like landslides etc. is not necessary just as the latest

developments of the various measurement techniques are not subject of the

following considerations.

Fig. 1: Interaction of several phases during the lifetime

of a construction

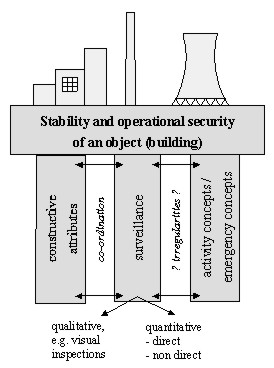

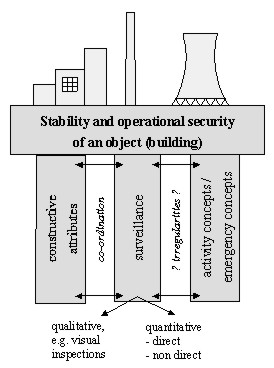

Aim and purpose of any surveillance is the earliest possible detection of

a damage, failure or an injury to the safe operation of a construction in

order to be able to react appropriately and in time. However, surveillance

is only one of the columns of the stability and operational security of a

construction, which has to be seen in a holistic way (Fig. 2). Usually the

construction itself is the most important column. The activity and emergency

concepts include but are not limited to aspects of normative and budgetary

constraints; integrity, material and structure damage assessment;

intensified surveillance and diagnostic technologies; lifetime and

utilization evaluation; maintenance and repair, out-of-service and

replacement decisions etc. The worldwide immense number of in-service

structures requires more and more investments in these concepts. In Ger-many

for instance, these investments equal the capital expenditure for new

buildings in the very near future (SFB 477-2000). Under these circumstances

it is quite clear that surveillance and analysis techniques gain more and

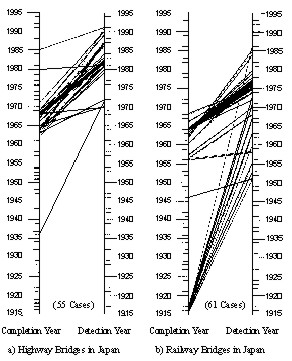

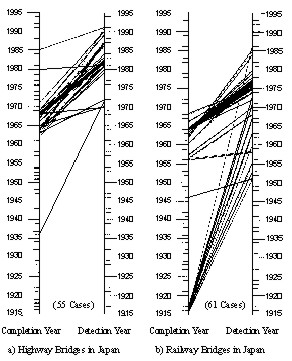

more significance. Fig. 3 shows the result of a study in Japan which

analyzes the time elapsed between the completion of highway and railway

bridges and the detection of a damage. The study makes evident that the

knowledge of the integrity of in-service structures on a continuous time

basis is an ultimate objective for owners and maintenance authorities

(Bergmeister 2000).

Fig. 2: Security concept for constructions

(Heunecke 2000)

Fig. 3: Completion year and damage year of highway (a)

and railway (b) bridges in Japan (SFB 477-2000)

It is self-evident that engineering surveying cannot cover all aspects

but is capable of providing essential contributions. It has to cooperate and

communicate with other fields of engineering. A common basis for

communication is being provided and already applied by system theory.

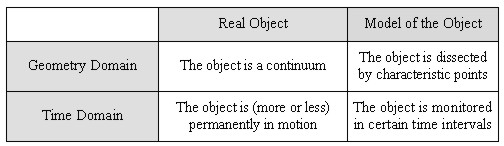

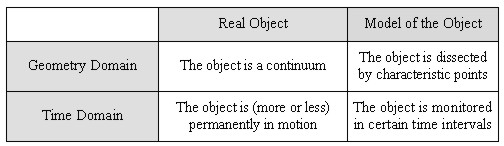

The surveillance of an object involved in a deformation process requires

the object as well as the process to be modeled. Conventionally, geodetic

modeling the object (and its surrounding) means dissecting the continuum by

discrete points in such a way that the points characterize the object, and

that the movements of the points represent the movements and distortions of

the object. This means that (only) the geometry of the object is modeled.

Furthermore, modeling the deformation process means conventionally to

observe (by geodetic means) the characteristic points in certain time

intervals in order to monitor properly the temporal course of the movements.

This means that (only) the temporal aspect of the process is modeled. This

kind of modeling and monitoring an object under deformation in space and

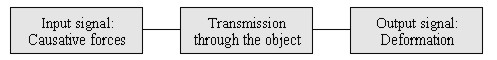

time has been the traditional geodetic procedure (Fig. 4). (It is not the

scope of this report to discuss the methods of the various other disciplines

dealing with the measurement of geometrical object changes. Their

proceedings fit more or less the scheme of Fig. 4.) Consequently, the

deformations of an object are described solely in a phenomenological manner.

Fig. 4: Geodetic modeling of deformation processes in

space and time

For the analysis in space and time there are in principle two classes of

models. Models testing the identity or congruence of the geometrical

properties of an object at two (or more) points of time are referred to as

models of congruence. They regard the time factor only implicitly. Models

de-scribing the deformation on the basis of a given or assumed function of

time, i.e. velocity, acceleration etc., are called kinematic.

Practically, the classical deformation analysis consists in a purely

geometrical comparison of the state of an object (represented by its

characteristic points) at two different points of time. The model for the

analysis of the observations does not consider the time intervals between

the observations nor the factors responsible for the deformation -

explicitly. Implicitly, however, some knowledge and information about the

presumable behavior of the object and the deformations in space and time

have to flow into a proper set-up of the deformation monitoring project.

The only input quantities of the evaluation model are the geodetic

observables l, while the output quantities are the coordinates x of the

characteristic points at certain moments of time. Since the 1960s the

identity or the congruence of the point coordinates with respect to the

so-called null or initial epoch have been statistically investigated. The

procedure is such that a null-hypothesis is formulated requiring the

coordinates to be the same as before. This null-hypothesis is included into

the usual least-squares (LS) GAUSS-MARKOV model:

(1)

Crucial aspect is the statistic test of the so-called mean gap (global

test of congruence)

, ,

(2)

(d vector of the coordinate differences,

Qdd

its cofactor matrix) on the basis of the probability relation

(3)

(Pelzer 1971). Basically the inherent differential

equation  is tested. is tested.

The global test detects whether there are any significant

coordinate differences. If there are any, then the next step is to localize

the point(s) which are causative. If need be, the movements of point

clusters can be generalized by rigid block movement or strain analysis, or

in terms of other systematic patterns. This kind of deformation analysis is

traditionally referred to as (conventional) deformation analysis, the

resulting point movement pattern as deformation model. Since this

‘geometrical’ deformation analysis (Chrzanowski et al. 1990) is based on the

hypothesis (1) of identical point coordinates, the deformation model is to

be called identity or congruence model (e.g. Welsch et al. 2000, pp.

369-418).

When automated measurement procedures came into use, the

temporal course of deformation processes was more and more considered in

evaluation models (e.g. Pelzer 1977b). If these models are restricted to the

investigation and description of object movements and distortions in space

and time, one speaks of kinematic models which have offered the opportunity

to extend the classical purely geometrical deformation analysis in

congruence models.

The intention of kinematic models is to find a suitable

description of point movements by time functions without regarding the

potential relationship to causative forces. Polynomial approaches,

especially velocities and accelerations, and harmonic functions are commonly

applied.

The relation of the space-time coordinates

x1

at an initial epoch t1 with respect to the coordinates

x2

at a consecutive epoch t2 are described by the time

dependent relation

. .

(4)

are the

mean velocity and acceleration of the points within the time interval

D

t. They represent the unknown parameters to be estimated. These

parameters are relevant to assess the process. The corresponding linearised

observation equation reads are the

mean velocity and acceleration of the points within the time interval

D

t. They represent the unknown parameters to be estimated. These

parameters are relevant to assess the process. The corresponding linearised

observation equation reads

.

.

(5)

This system represents in general the set-up of a regression analysis. In

expansion of the basic regression analysis sequential adjustment algorithms

are an important mathematical tool which are in a formal manner a transition

to Kalman-filtering techniques, and are suitable to make use of consecutive

observations for updating and predicting the state of a process under

investigation (Pelzer 1987; Welsch et al. 2000, pp. 419-446).

4.

Dynamic Systems and

Advanced Deformation Analysis - Systematization of Deformation Models

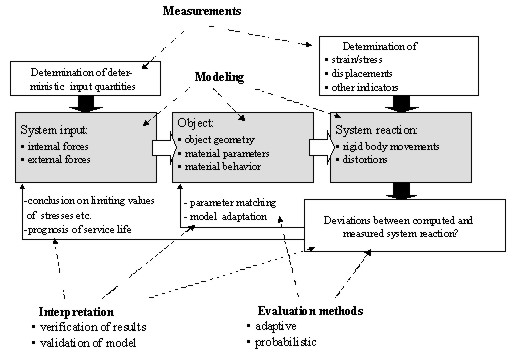

Advanced evaluation models for deformation analysis do not only consider

the change of the geometry of an object in space and time. They rather

investigate and incorporate also the influencing factors (causative forces,

internal and external loads) causing the deformation. They regard in

addition the object's physical properties (material constants, extension

coefficients, etc.) which are characteristic and responsible for the

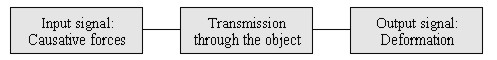

response of the object to the acting forces. The three elements 'acting

forces' as input signal, 'transmission through the object' as transfer

process, and 'response of the object' as output signal form a causal chain

or - according to the terminology of system theory - a dynamic process or a

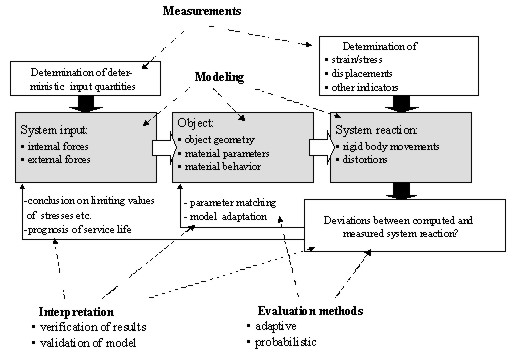

dynamic system (Fig. 5).

Fig. 5: Deformation as an element of a dynamic system

In recent years engineering sciences have established a standardized

mathematical description of the temporal behavior of dynamic systems

according to system theory. In the following the variants of dynamic systems

are characterized:

- Dynamic (cause-response) systems: Changes of input signals release a

time-dependent process of adaptation of the system with the consequence

that the reaction of the output side is delayed: a dynamic system has a

memory. This is the general case. Special cases can be distinguished with

respect to the factor time. There are two kinds of dynamic systems:

a) dynamic systems as such react as in the general case: the

deformations as the output signal are a function of time and (varying)

loads. The knowledge of the memory of the sys-tem is the basis for

prediction;

b) static systems can be seen as a special case of dynamic systems.

They react immediately (without a memory) to the change of the

causative forces: the new state is a state of equilibrium. The

deformations are a function of changed loads only.

- Autonomous (free) systems are not subject to acting forces. These

systems can nevertheless be in motion. There are two kinds of autonomous

systems:

c) kinematic systems are in motion; the motion can be described as

a function of time;

d) random walk systems are in motion, but the motion is random, a

function of time cannot be established apriori.

Modeling a dynamic process according to Fig. 5 is by far more

comprehensive than modeling solely the deformation as the reaction of the

object in space and time. The complexity of dynamic modeling makes the

requirement of interdisciplinary cooperation obvious.

Fig. 6: Dynamic modeling of a construction

To set an example, the technical system 'construction' (Fig. 6) is

stressed by internal and external forces or loads (like traffic load, wind

pressure, backwater pressure, temperature etc.). These so-called input

quantities (input signal) have to be determined by measurements. The

reaction of the system is deformations (e.g. rigid body movements, strain).

In order to model (calculate, predict) the reaction of the system as the

output signal, the transmission through the object (transfer function) has

to be modeled as well. Parameters to do this are in particular the

construction's geometry, its material parameters and the assumed material

behavior. If the two elements - input signal and transfer function - are

known, the dynamic process can be modeled and the reaction can

quantitatively be predicted (if need be by the aid of the Finite Element

Method or another computation tool). This kind of a dynamic model is also

referred to as a deterministic (Chrzanowski et al. 1990), mechanical or

computational model. Consequently, error propagation should be taken into

consideration (e.g. Kuang 1993; Szostak-Chrzanowski et al. 1994; DIN

1319-1997). If, how-ever, in addition also the reaction of the system, i.e.

the deformations, is determined by (geodetic) measurements, the full

potentiality of dynamic models becomes obvious (integrated models). The

comparison of the predicted to the observed deformations may reveal some

deviations which are called 'innovation' (Fig. 10). The innovation is the

basic element for KALMAN-filtering techniques. Fig. 6 accentuates the

components of the investigation and the assessment of a process: modeling

the process (theory), performing the measurement of input and output

quantities, evaluating functional and stochastic relationships, and -

finally - assessing the findings by verification and validation. In this way

the model can be calibrated and the dynamic process be identified. Worldwide

numerous research centers are active to adapt and to apply this general

interdisciplinary scenario.

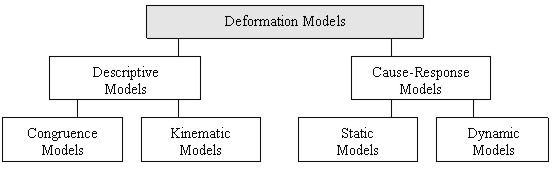

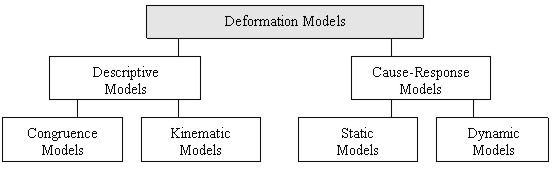

Summing up these comments and referring to the variants of dynamic

systems, according to sys-tem theory in principle the following four

categories of models can be distinguished for the evaluation of deformations

(Fig. 7):

Fig. 7: Hierarchy of models in geodetic deformation

analysis (Welsch and Heunecke 1999)

Descriptive models like the congruence and kinematic models are already

described in par. 3. The class of cause-response models are the ones to be

characterized in the following in more details.

For many applications in our days the understanding of engineering

surveying intends - as out-lined above - to consider not only the space and

time domains of deformations, but rather the whole chain of a dynamic

process, i.e. to incorporate also the causative forces acting on the object

and the geometrical and physical properties of the object itself. With

today's technology the basic requirements thereto are available: the

possibility of measuring and recording the input and output signals of a

dynamic process are in the same way at hand as the computer capacities are

sufficient to perform the necessary algorithmic calculations. As practice

shows, in many instances the main difficulty is the availability of

appropriate software programs to process the data accordingly.

Static models describe the functional relationship between stress and

strain. Stress is caused by loads or the forces acting on the object and

resulting in strain as the object's geometrical reaction. Since the factor

time is not explicitly considered in static models, the object has to be

sufficiently in equilibrium in both the observation epochs, i.e. before and

after the load has been brought up on the object. Sufficiently in

equilibrium means, the object has to appear (more or less) motion-less

during the time of observation. The movements and distortions of the object

are considered a function of only the load but not the time. For static

models, the physical and geometrical structure, the material parameters and

other characteristic quantities of the object have to be known and to be

formulated in terms of differential equations expressing the stress-strain

relationship of the object. This requirement leads to another term of

characterization of static models: static models are parametric (see below),

structured or deterministic models. Other terms are state or theoretical

models; the evaluation applying static models is also called 'model

approach'. Static models are frequently applied, if the load-carrying

capacity of structures like bridges, pylons etc. is to be tested. An example

is given in par. 6.2.

Dynamic models are the most general and comprehensive models because they

aim to describe the reality of dynamic systems completely. The movements and

distortions of the object are considered a function of both load and time.

This implies time varying stresses and time varying re-actions. In contrast

to the static situation the object is permanently in motion. Monitoring such

a situation requires permanent and automatic observation procedures. Dynamic

models can be parametric or non-parametric (see below). Other terms for

non-parametric models are attitude or statistical, experimental or empirical

models; the evaluation applying non-parametric models is also called

'operational approach'. So far, there are hardly any parametric dynamic

models being used for the geodetic analysis of dynamic processes, at least

not for the so-called multiple input - multiple output (MIMO) situations.

Almost all dynamic models applied to deformation analysis are

non-parametric.

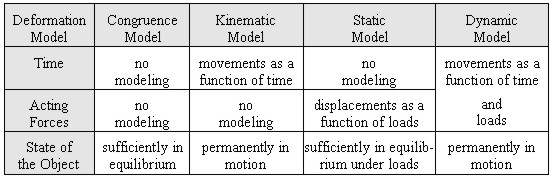

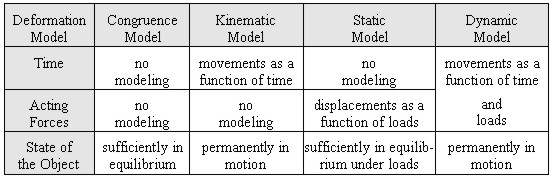

In Fig. 8 the four categories of deformation models are characterized by

their capacity of taking the factors 'time' and 'load' into account.

Fig. 8: Characterization and classification of

deformation models (Welsch and Heunecke 1999)

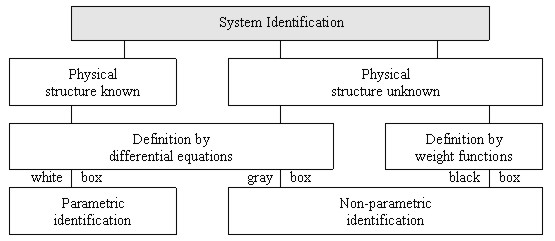

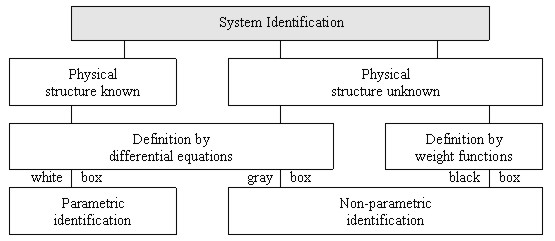

In system theory, the set-up of an appropriate mathematical-physical

representation of the transfer function of a dynamic system is called system

identification. System identification can be achieved, if the input as well

as the output signals are available as measured quantities. The feasibility

of how a model for the transfer function can be set up, is decisive for the

choice of a parametric or a non-parametric identification (e.g. Heunecke et

al. 1998, Heunecke and Welsch 2000), see Fig. 9.

Fig. 9. Methods of system identification (Heunecke 1995;

Welsch 1996)

If the physical relationship between input and output signals, i.e. the

transmission or transfer process of the signals through the object or - in

other words - the transformation of the input to out-put signals, is

supposed to be known and can be described by differential equations, then

the model is called a parametric model (structural model). The system

identification is carried out in a so-called 'white box' model. Of course,

white box models are - as it is the case with all models - an idealization

of the real world.

The fundamental equation of any dynamic model of a system (Welsch et al.

2000, pp. 461-474) is the differential equation of linear dynamic

elasticity:

(6)

(6)

y(t) is the system input, the acting

forces which have, if need be, to be complemented by the disturbance noise;

x(t) and its derivatives are the system output (to be

monitored e.g. by geodetic means); the matrices K, D,

and M

contain - in case of an application of mechanics like a building or another

construction - material and design parameters for rigidity, damping and

mass. Depending on the actual problem individual sets of parameters or

measurements can be inapplicable. For instance, for the investigation of

characteristic oscillations the damping matrix is to be omitted, and with

slow motions the mass can be neglected (Heunecke 1995, Jaeger et al. 1997).

For static models (Welsch et al. 2000, pp. 447-459) the

special case of a dynamic model

(7)

(7)

is applicable. Static systems are characterized by

capturing a new state of equilibrium after assuming a load with y(t)

= const.

As a trivial form the case

(8)

(8)

is of special interest. It comprises the models of

identity and congruency, i.e. the most common application of deformation

monitoring based on geodetic networks; see par. 3.

In the context of structural models it is of importance, that coordinate

systems are introduced as reference systems. Coordinates are intermediate

quantities of the evaluation procedure. They are called state parameters

comprised in the state vector. Apart from coordinates also additional

(physical) state parameters may be used. In the sense of system theory state

parameters serve for the description of the inherent relations of the

system; they form the state space. The investigation of a dynamic process

with the help of a structural model is based on the analysis of the state

space.

If with parametric system identification only the time dependence rather

than the local variation of the process is considered, the system can be

defined by 'lumped parameters'. Ordinary differential equations are

sufficient in this case. If with parametric system identification apart from

the time dependence also the local variation of the parameters is

considered, the system has to be defined by 'distributed parameters'. This

leads to partial differential equations. If the differential equations are

set up for restricted areas only, the partial differential equations can be

replaced by ordinary differential equations which are, however, effective

only within these limited areas (local discretisation). The solutions found

for the individual areas have to be joined to each other taking into account

boundary conditions for a smooth connection. The result represents an

approximate solution of the original differential equation. A numerical

procedure is given by the Finite Element Method (FEM) which is today the

standard computation method for any kind of structural problems in civil

engineering and in many other engineering sciences.

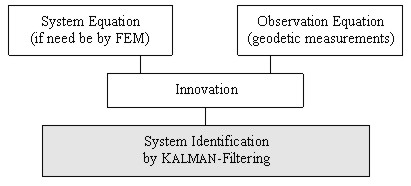

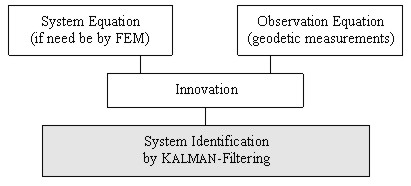

KALMAN-filtering is the most popular and universal estimation tool for

system identification and can be applied to all kinds of models in Fig. 7

and 8, resp. (Welsch et al. 2000, pp. 285-317). The essential idea can be

explained as follows. On the one side there is the theory modeling the

object by differential equations. These equations form the so-called system

equation. On the other side there are measurements monitoring the real

behavior of the object. The measurements are formulated as the so-called

observation equation. KALMAN-filtering is a technique to combine both

equations by least squares adjustment in order to gradually improve the

identification of the sys-tem. For this the innovation, i.e. the difference

between the predicted and the measured reaction of the object, is essential.

Fig. 10: Substance of KALMAN-filtering (Heunecke 1995)

Input quantities Y of a Kalman-filtering

process are the previous state vector

xk

at

time tk, the deterministic input quantities

uk

(acting forces), the disturbance quantities

wk

and the monitoring observations

lk+1

including the respective covariance matrices:

. .

(9)

The quantities of main interest X are the

already mentioned innovation dk+1, the

filtered (updated) state vector  and the residuals

and the residuals and and

. These quantities can be

computed through the linear equation (10) with respect to the predicted

state vector . These quantities can be

computed through the linear equation (10) with respect to the predicted

state vector  and the observations lk+1;

Kk+1

is the so-called gain-matrix and

Dk+1 is the

covariance matrix of the innovation:

and the observations lk+1;

Kk+1

is the so-called gain-matrix and

Dk+1 is the

covariance matrix of the innovation:

. .

(10)

The algorithm can be used whenever a system equation can

be established. In a congruence model the system equation degenerates to the

prognosis of identical coordinates; deterministic input quantities

uk

are not modeled. For a kinematic approach the state vector contains

coordinates, velocities and accelerations. Kalman-filtering in deformation

analysis is mainly applied to static or dynamic models with system equations

set up by the Finite Element Method, see par. 6.2.

5.2 Non-parametric models

If there is no way of modeling the geometrical and the

physical structure of a system, the relationship between input and output

signals can be formulated only in the sense of regression and/or correlation

analysis (behavior model). Time series analysis is helpful. System

identification means then the determination (estimation) of the

regression/correlation coefficients. Commonly these coefficients or kernels

are called parameters, too, although they are not the physical parameters of

the process under investigation; they relate rather the input signals to the

output signals without any physical significance. These non-parametric

models are therefore also called ‘black box’ models. It means that system

identification is based on measurements only but not on a mechanical model;

it is symptom but not model orientated.

The most general description of non-parametric models is

a set of partial differential equations. In the case of a ‘single input –

single output model’ (SISO) it is given by an ordinary differential equation

which can be established (Ellmer 1987; Welsch 1996) by the approach

. .

(11)

If one proceeds from the differential to a difference

equation, the model is also known as the so-called ARMA (autoregressive

moving average) model:

. (12) . (12)

The unknown coefficients

ak and

bk

are the parameters to be estimated in the identification procedure. The

boundary values q and p represent the continuance of the

memory: at time tk the model recollects all the input and

output events back to those boundaries.

Characteristic for this elementary non-parametric model

is the fact, that for q > 3 and p > 0 a physically meaningful

model structure gets lost, although the coefficients have to be regarded as

functions of the material and design parameters of the system. For q

£ 3 and p = 0, however, the parameters can physically be

interpreted. In other cases the model is a ‘gray box’. However, the

distinction between the different kinds of models – white, gray and black –

is gradual, and depends on the appreciation of terms like ‘parameter’ or

‘physical structure’.

The ARMA-model consists of a recursive and a

non-recursive part:

.

(13) .

(13)

For p = 0 the model is autoregressive: the actual

observation xk is considered a linear combination of the

past observations and the present system input yk. For

q

= 0 the model becomes non-recursive: the actual system output is a linear

combination of the present and the past system inputs. The coefficients

bj

can then be regarded as the factors of a regression analysis.

For continuous observations the representation of the

non-recursive (linear) model is the convolution integral (Strobel 1975)

,

(14) ,

(14)

where  is

the so-called weight function which plays - as above - the role of

regression analysis parameters. is

the so-called weight function which plays - as above - the role of

regression analysis parameters.

For the treatment of non-linear unstructured problems for

instance the so-called Volterra-model (Wernstedt 1989) has been developed:

(15)

(15)

+ higher order terms.

In the discrete case these models can be written in form

of a summation or multiple summation equation, resp. (Pfeufer 1990, 1993).

Non-parametric models can be applied to a great variety of systems and

processes.

Time series analysis (Welsch et al. 2000, pp. 319-367) as

such is another method of system identification and is frequently applied in

non-parametric situations. The most significant information to be calculated

in the time domain of a time series is its expectation value and the

auto-covariance function which informs of variance of the process observed.

Comparing the input and the output time series by calculating the

cross-covariance function, one obtains information about the correlation of

the two time series and whether the reaction of the system is delayed with

respect to the input signal (phase shift). If one applies

Fourier-transformations to switch from the time to the frequency domain,

characteristic frequencies of the process can be detected. The output signal

comprises only frequencies which are also contained in the input signal.

Consequently, frequencies which are in the output but not in the input

signal, can give clues that there may be more than the investigated factors

influencing the system. Time series analysis as such

has a wide range

of applications in geodetic deformation analysis (e.g.

Kuhlmann 1996).

Recently new analysis techniques have been adopted from

control engineering: neural networks and fuzzy logic have been used to set

up models for the identification of input-output systems (Heine 1999).

In practice, a comprehensive and complete analysis of a deformation

process can hardly be carried out applying only one kind of the above

mentioned models. In almost all instances, experiments have to be made to

find the best method and procedure, even 'trial and error' should not be

excluded. This is especially relevant, if the geometrical and/or physical

model to be chosen is not clear but questionable so that the problem of

model separability arises (Lu 1987, Chen and Chrzanowski 1994). This point,

however, is not specified further on in detail.

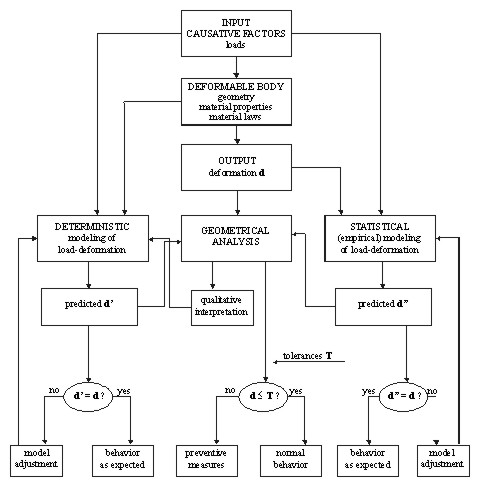

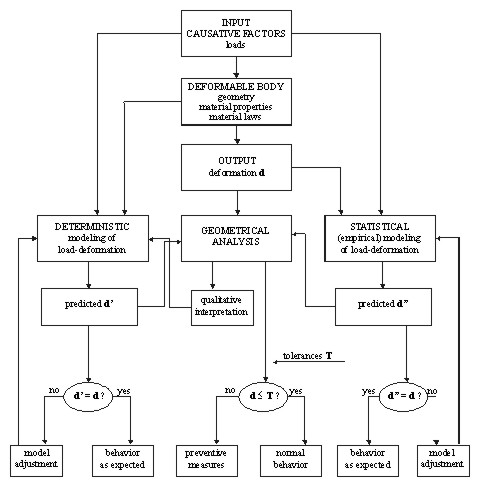

A practical approach may be the following: According to Chrzanowski et

al. (1990) the integrated analysis of deformation surveys includes the

geometrical analysis of the status of the deformable body and the physical

interpretation, i.e. the identification of the dynamic process. Fig. 11

shows an idealized flowchart of the integrated deformation analysis.

'Integrated' means the combination of the geometrical analysis with

prediction models.

Fig. 11: Flowchart of integrated deformation analysis

(Chrzanowski et al. 1990)

The latter can be achieved by applying either the 'statistical', i.e. the

non-parametric, or the 'deterministic', i.e. the parametric, method. Once

the load-deformation relationship is established, the results may be used

for the development of prediction models. Through the comparison of

predicted deformations with the results of the geometrical analysis of the

actual deformations, i.e. the innovation, a better understanding of the

mechanism of the dynamic system is possible. The new knowledge can be used

in 'model adjustments' the results of which lead iteratively to what has

been referred to (Fig. 6) as parameter matching and model adaptation.

A typical example for the application of parametric modeling of a dynamic

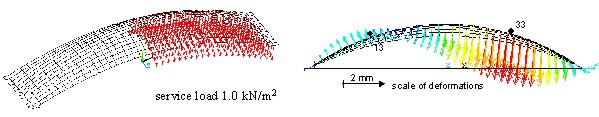

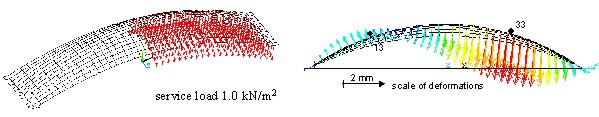

system is load trials on constructions. The static behavior of a 10.0 m x

2.0 m shell structure, made of bricks, was investigated (Hesse et al. 2000).

The semilateral surface loading (1.0 kN/m², loading step No. 6) of the

structure and the settlements predicted using FEM is shown in Fig. 12. The

surface loading was stepwise increased from zero up to 4.0 kN/m2 (loading

step No. 24). The envisaged break-down of the structure could, however, not

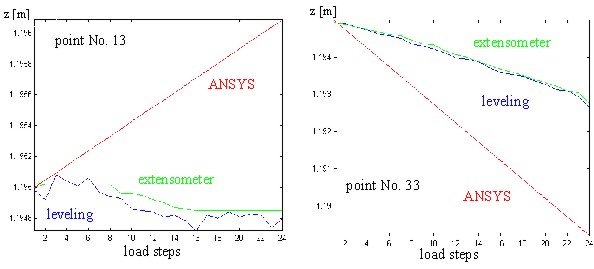

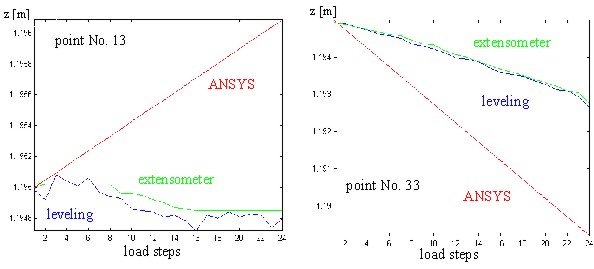

be achieved. For two of the monitored points (No. 13 and No. 33) the

predicted settlements (ANSYS, system equation) and the displacements

measured by means of leveling and extensometers (observation equation) are

depicted in Fig. 13. The discrepancy between the prediction and the

measurements, in terms of KALMAN-filtering the 'innovation', is quite

striking.

Fig. 12: Semilateral loading of a shell construction and

predicted settlements (Hesse et al. 2000)

Fig. 13: Comparison of predicted and measured settlements

of points No. 13 and 33 (Hesse et al. 2000)

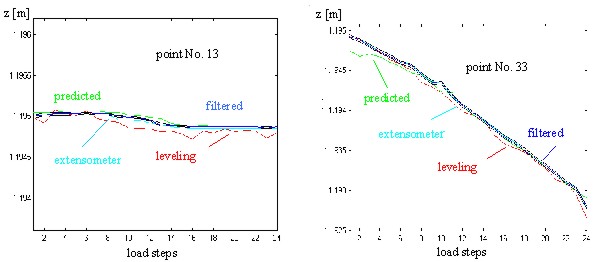

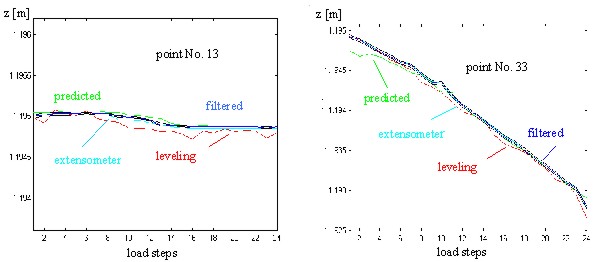

Fig. 14: Settlements of points No. 13 and 33 after the

adaptive filtering process (Hesse et al. 2000)

After adaptive KALMAN-filtering the innovation is reduced so that the

predicted and filtered settlements are in accordance with the measured

values (Fig. 14), there is no significant difference anymore. Adaptive

filtering means to identify, i.e. to estimate the material parameters

(Young's modulus) of the structure as additional unknown state parameters

(state vector augmentation). As a result, the material parameters (physical

state quantities) obtain values which differ quite a bit from the original

assumptions. Based on the results of the parametric identification, the

assessment of the stability and the operational security of the structure is

now much more realistic and reliable then it was before.

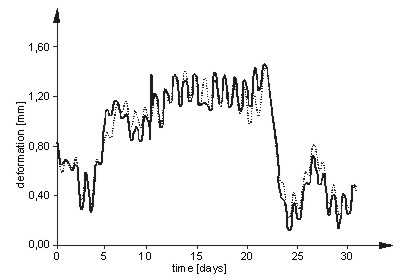

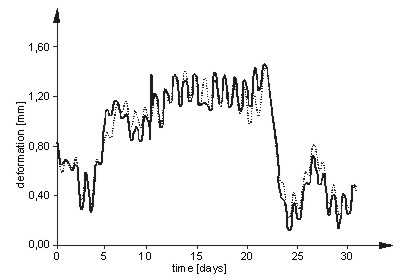

The following example discusses the reaction of the foundation pillars of

a large turbo engine due to temperature variations (Ellmer 1987). Due to

irregularities and major gaps during the data acquisition of the temperature

and deformation measurements, in a first step interpolation and

approximation procedures were applied to the time series in order to achieve

equispaced data which are required for the analysis models.

Fig. 15: Measured (¾ ) and

modeled (× ×

×

) deformation of a pillar supporting the turbine table

In a second step Fourier transformations were used to get preliminary

information on the behavior of the system. The last step relates the

temperature changes to the deformations by a SISO identification model which

considers the fact that temperature changes effect the foundation pillars

over a longer period of time. This model is given by equation (13)

which is restricted, however, to the estimation of the non-recursive

parameters b0, ... , bp only, where p

stands for the memory-length. The solution includes p

= 30 significant parameters bk. This model is able to

demonstrate that most of the deformations can be explained by the recorded

temperature variations (Fig. 15).

Fig. 16: Deformation of the table plate as caused by a

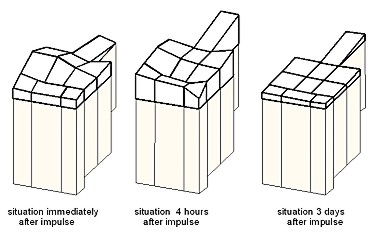

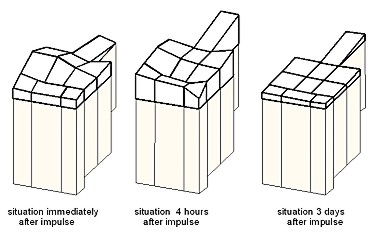

unit impulse of 1 K ( × = 0,01 mm)

Fig. 16 depicts the reaction of all the pillars of the turbine table to

an input impulse of 1 K immediately after the impulse, after 4 hours and

after 3 days. The point of this sort of non-parametric system identification

is that the model describes the reaction of the object to be monitored in a

'black box' manner. It is meaningful, because it relates input signals

(temperature variations as physical causative forces) to output information

(deformations of the pillars). It does not contain, however, any information

about the structure or at least the significant material parameters, e.g.

the coefficient of expansion, of the system which could make evident why the

system reacts as it obviously does. The physical interpretation of dynamic

processes on the basis of non-parametric models is therefore always limited;

the interpretation is symptom oriented.

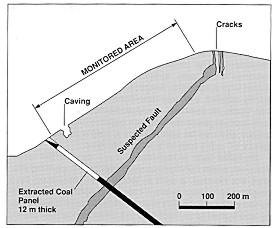

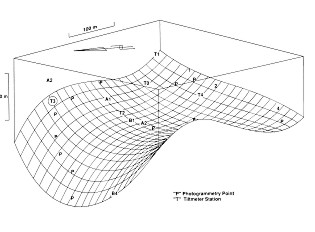

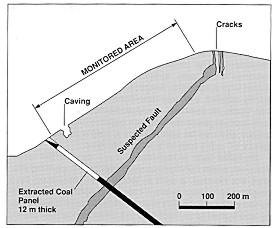

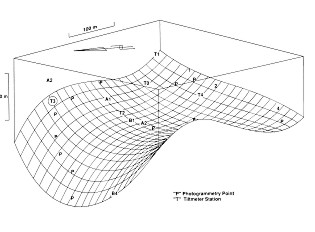

Another typical application of deformation analysis is ground subsidence.

The Sparwood coal fields, British Columbia, for instance were observed and

analyzed by Chrzanowski et al. (1990). The purpose of the surveys was to

monitor ground movements caused by the extraction of a 200 m by 700 m panel

of a 12 m thick and steeply inclined coal seam (Fig. 17). Three types of

monitoring observations were used under rough climate conditions:

tacheometric geodetic measurements, aerial photogrammetric surveys and

continuous measurements of changes of ground tilts by automated biaxial

tiltmeters. Between 1980 and 1982 the panel extraction (input quantity)

produced displacements of up to 2.5 m with surface cavings near the coal

outcrop and cracks at the mountain ridge. The best fit model of the

displacement field of the complicated deformation pat-tern (Fig. 18) was

obtained by applying the combined analysis of all three types of

observations (Chrzanowski et al., 1986). The analysis led to a suspicion

that there was either a geological fault or a discontinuity in the rock mass

was created by the progressing mining activity.

Fig. 17: Cross-section of the subsidence area

(Chrzanowski and Szostak-Chrzanowski, 1986)

Fig. 18: Ground subsidence model obtained from geodetic,

photogrammetric and tiltmeter measurements (Chrzanowski et al. 1990)

Fig. 19: FEM displacements versus observed values in the

Sparwood coal fields

(Chrzanowski and Szostak-Chrzanowski, 1986)

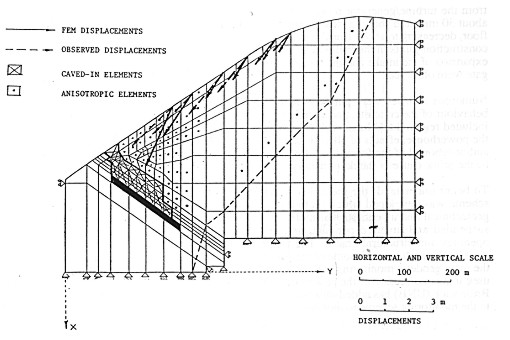

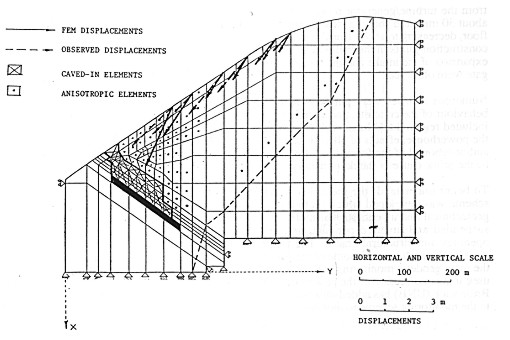

The phenomenon as a whole could not be readily explained. Therefore, a

deterministic FE modeling of the subsidence was performed (Chrzanowski and

Szostak-Chrzanowski 1986). The modeling was difficult due to the fact that

besides the unknown fault parameters also the values of the in situ Young's

modulus of the rock were not well known. However, using the results of the

geometrical analysis, the deterministic model could be calibrated

(adaptation of Young's modulus, insertion of the assumed fault parameters

into the analysis). Two FE models were analyzed: one without the assumed

discontinuity and one with the insertion of the suspected fault. The FEM

results with the fault gave incomparable better agreement with the observed

values of the displacements. The final result obtained from this static

model is shown in Fig. 19. The findings of the integrated analysis led to

the closing of the mining operation to prevent a potential slope failure.

The example demonstrates that parametric description, i.e. deterministic

modeling, of geological phenomena, though difficult to perform, may lead to

useful physical interpretation of deformations if properly combined

(calibrated) with the geometrical model. Apart from parameter matching

according to Fig. 6 also the identification of the unknown structural

properties as for instance the fault zone geometry is crucial for an

appropriate solution.

For many reasons the development and application of dynamic models is of

great significance for the investigation of technical and natural phenomena.

They offer the most far-reaching possibilities for the analysis,

interpretation and the prognosis of processes which are essential aspects of

deformation analysis. Therefore, evaluation procedures are to be aimed at

which are able to fulfil the following essential tasks:

- processing of big amounts of data gathered by different sensor systems

(hybrid data) monitoring the input and output signals of a dynamic system

- identification of the system behavior applying models which are

adequate with respect to the process to be monitored

- treatment of disturbing influences by filtering

- prediction of the reactions of the system, if it acts regular

- assessment of the reaction of the system, if it undergoes irregular or

even extreme influences

- separation of the influences caused by the individual input factors

- determination of the main influencing factors

- possibility to control the process via factors which are controllable

- optimization of monitoring and observation plans due to a better

knowledge of the process

- comprehensive interpretation of the results achieved due to the

knowledge of identifiable and physically well-founded parameters of the

process.

In many cases there exists only poor knowledge of the internal and

external connections of a process. Therefore a universal, generally accepted

single scheme for the investigation of different objects cannot be set up.

The numerous classes of dynamic models as discussed in this report offer,

however, a great variety of possibilities for a pertinent treatment of a

great number of processes and objects. The development in this domain has

been pushed forward considerably in the previous years, and will be advanced

in the future.

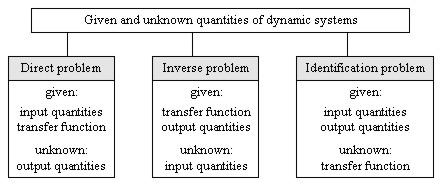

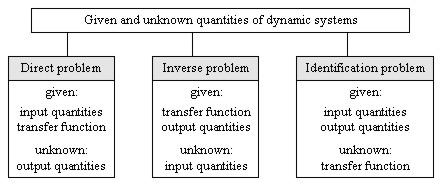

Fig. 20: Essential problems of dynamic systems (after

Natke 1983)

System analysis (direct problem) requires the input quantities and the

transfer function to be known. The reaction of the system is in this case

the unknown quantity. At last, the identification problem derives the

transfer function from observed input and output signals.

The following general problems can be treated and solved for with the

help of dynamic modeling (Fig. 20). In case of the direct or design problem,

the system behavior (transfer function) is regarded to be known, so that the

output signal can be computed (predicted). The inverse problem (back

analysis, reverse engineering) assumes the reaction and the transfer

function as given and analyses the causative factors (e.g. Kersting 1992).

From the geodetic point of view a contribution can be given to system

identification by verifying the system's behavior on the basis of input and

output signals to be measured. Transitions between the three general

problems are fluent.

System identification is performed to determine the physical status of a

deformable body, the state of internal stresses and, generally, the

load-deformation or stress-strain relationship. Once this relationship is

established, the results (system equation) may be used for the development

of a prediction model. Through the comparison of predicted deformations with

the result of the geodetic analysis of the actual deformations (observation

equation), a better understanding of the mechanism of the deformations is

achieved. Thus, engineering surveying may significantly con-tribute to a

realistic interpretation of a dynamic process under investigation.

On the other hand, the prediction models which, in most cases, are

developed by other specialists, supply important information to the

surveying engineer about the deformations to be expected, facilitating the

design of the monitoring scheme as well as the selection of the deformation

analysis model in the geometrical realm. Unfortunately, in many cases this

scenario of a truly interdisciplinary approach to the design and analysis of

deformation surveys has not yet been implemented in practice. The reasons

are an inadequate understanding of the methods of system identification by

surveying engineers, and an inadequate familiarization of other specialists

with the comparatively new methods of advanced geodetic analysis of dynamic

processes. The gain of knowledge to be achieved by the combination of

techniques developed in system theory like KALMAN-filtering with techniques

applied in civil engineering like FEM and engineering surveying, e.g.

statistical testing procedures and reliability considerations, offers new

aspects for the future.

Within the last few years, one can see some progress in the right

direction, not only within the geodetic community, with more scientific

papers on the identification of dynamic systems presented at surveying and

geodetic meetings, but in the meantime also at conferences of other

disciplines. However, these developments must be intensified. The trend will

be supported and enhanced by a commonly acknowledged terminology. The

potentiality of all the possibilities of analyzing dynamic systems by

appropriate models and methods - from geometrical descriptions to highly

sophisticated integrated models and analysis techniques - has to be

exploited.

Ad-Hoc Committee of FIG (1993) under the leadership of A.

Pfeufer: G. Milev, W. Proszynski, G. Steinberg, W.F. Teskey, W. Welsch:

Report of the Ad-Hoc Committee on Classification of Deformation Models and

Terminology. 7th International FIG-Symposium on Deformation

Measurements. Department of Geomatics Engineering, The University of

Calgary, Alberta. Proceedings, pp. 66-76

Ad-Hoc Committee of FIG (1994) under the leadership of A.

Pfeufer: G. Milev, W. Proszynski, G. Steinberg, W.F. Teskey, W. Welsch:

Classification of Models for the Geodetic Examination of Deformations.

Perelmuter Workshop on Dynamic Deformation Models. The Technion, Haifa,

Israel. Proceedings, pp. 94-108

Bergmeister, K. (2000): Integrated Monitoring of Bridges.

Colloquium of SFB 477, Technical University Braunschweig, Germany.

22.06.2000

Boljen, J. (1983): Ein dynamisches Modell zur Analyse

und Interpretation von Deformationen. Wissenschaftliche Arbeiten der

Fachrichtung Vermessungswesen der Universität Hannover, No. 122

Boljen, J. (1984): Statische, kinematische und dynamische

Deformationsmodelle. Zeitschrift für Vermessungswesen 109, pp.

461-468

Bonn (1978): 2nd International Symposium on

Deformation Measurements. Bonn, 25.-28.09.1978. Hallermann, L. (ed.):

Vermessungswesen

Band 6. K. Wittwer, Stuttgart

Chen, Y.Q. (1983): Analysis of Deformation Surveys - A

Generalised Method. Department of Surveying Engineering, University of

New Brunswick. Technical Report No. 94

Chen, Y.Q. and A. Chrzanowski (1994): An Approach to

Separability of Deformation Models. Zeitschrift für Vermessungswesen

119, pp. 96-103

Chen, Y.Q. and A. Chrzanowski (1986): An Overview of the

Physical Interpretation of Deformation Measurements. Deformation

Measurements Workshop Modern Methodology in Precise Engineering and

Deformation Surveys - II. MIT, Cambridge, Mass., USA. Proceedings,

pp. 207-220

Chrzanowski, A. (1981) with contributions by members of

the FIG Ad-Hoc Committee: A Comparison of Different Approaches into the

Analysis of Deformation Measurements. FIG-XVI Congress, Montreux,

09.-18.08.1981. Proceeding, paper 602.3

Chrzanowski, A. (1992): Recommendations. 6th

International FIG-Symposium on Deformation Measurements.

Wissenschaftliche Arbeiten der Fachrichtung Vermessungswesen der Universität

Hannover,

No. 217, Hannover 1996

Chrzanowski, A. (1999): Review of Activity FIG Working

Group 6.1 Concerning Methods of Deformation Analysis and Classification of

Deformation Models. 9th International FIG-Symposium on

Deformation Measurements, Olsztyn, 27.-30.09.1999. Proceedings,

pp. 410-415

Chrzanowski, A., Y.Q. Chen, J. Secord (1982): On the

Analysis of Deformation Surveys. 4th Canadian Symposium on Mining

Surveying and Deformation Measurements. The Canadian Institute of Surveying,

Banff, 07.-09.06.1982. Proceedings

Chrzanowski, A., J. Secord (1983): Report of the Ad-Hoc

Committee on the Analysis of Deformation Surveys. XVII. FIG-Congress,

Toronto, 01.-11.06.1983. Proceedings, paper 605.2

Chrzanowski, A., Y.Q. Chen (1986): Report of the Ad-Hoc

Committee on the Analysis of Deformation Surveys. XVIII. FIG-Congress,

Toronto, 01.-11.06.1986. Proceedings, paper 608.1

Chrzanowski, A., Y.Q. Chen, P. Romero and J. Secord

(1986): Integration of Geodetic and Geotechnical Deformation Surveys in

Geosciences. Tectonophysics 130, pp. 369-383

Chrzanowski, A., A. Szostak-Chrzanowski (1986):

Integrated Analysis of Ground Subsidence in a Coal Mining Area: A Case

Study. Deformation Measurement Workshop, Mass. Institute of Technology,

31.10. – 01.11.1986. MIT, Cambridge, Mass., USA. Proceedings, pp.

259-274

Chrzanowski, A., Y.Q. Chen, A. Szostak-Chrzanowski, J.M.

Secord (1990): Combination of Geometrical Analysis with Physical

Interpretation for the Enhancement of Deformation Modelling. XIX. FIG

Congress, Helsinki 1990, Proceedings, Com. 6, pp. 326-341

DIN 1319, Part 4 (1997): Basic Concepts of

Measurements, Treatment of Uncertainties in the Evaluation of Measurements.

German Standard

Ellmer, W. (1987): Untersuchung temperaturinduzierter

Höhenänderung eines Großturbinentisches. Schriftenreihe des Studiengangs

Vermessungswesen, Universität der Bundeswehr München, No. 26, Neubiberg

Felgendreher, N. (1981): Studie zur Erfassung und

Verarbeitung von Meßdaten dynamischer Systeme. Deutsche Geodätische

Kommission, Reihe B, No. 256, München

Felgendreher, N. (1982): Zu Modellierungsproblemen bei

dynamischen Systemen. Zeitschrift für Vermessungswesen 107, S.

125-129

Heck, B., J.J. Kok, W. Welsch, R. Baumer, A. Chrzanowski,

Y.Q. Chen, J.M. Secord (1982): Report of the FIG Working Group on the

Analysis of Deformation Measurements. In: I. Joó and A. Detreköi (eds.):

Deformation Measurements, pp. 337-415. Akademiai Kiadó, Budapest

Heine, K. (1999): Zur Beschreibung von

Deformationsprozessen durch Volterra- und Fuzzy-Modelle sowie Neuronale

Netze. Deutsche Geodätische Kommission, Reihe C No. 516, München

Hesse, C., O. Heunecke, M. Speth, I. Stelzer (2000):

Belastungsversuche an einem Schalentragwerk aus Ziegelsteinen. In:

Schnädelbach und Schilcher (Hrsg.): XIII. Internationaler Kurs für

Ingenieurvermessung München, 13.-17. 03. 2000. Proceedings, pp.

340-345

Heunecke, O. (1995): Zur Identifikation und

Verifikation von Deformationsprozessen mittels adaptiver Kalman-Filterung

(Hannoversches Filter). Wissenschaftliche Arbeiten der Fachrichtung

Vermessungswesen der Universität Hannover, No. 208

Heunecke, O., H. Pelzer, W. Welsch (1998): On the

Classification of Deformation Models and Identification Methods in

Engineering Surveying. XXI. FIG-Congress 1998, Brighton. Proceedings,

Com. 6, pp. 230-245

Heunecke, O. (2000): Ingenieurgeodätische Beiträge zur

Überwachung von Bauwerken. Workshop ‘Dynamische Probleme – Modellierung und

Wirklichkeit’, Hannover, 05.-06.10.2000. Proceedings, pp. 159-176

Heunecke, O., W. Welsch (2000): A Contribution to

Terminology and Classification of Deformation Models in Engineering Surveys.

Journal of Geospatial Engineering, vol. 2. No. 1, pp. 35-44, Hong

Kong

Jaeger, R., U. Haas, A. Weber (1997): Ein ISO 9000

Handbuch für Überwachungsmessungen. Schriftenreihe des Deutschen Vereins

für Vermessungswesen No. 27, pp. 415-427, K. Wittwer

Kersting, N. (1992): Zur Analyse rezenter

Krustenbewegungen bei Vorliegen seismotektonischer Dislokationen.

Schriftenreihe des Studiengangs Vermessungswesen der Universität der

Bundeswehr, No. 42, Neubiberg

Krakow (1975): 1st International Symposium on

Deformation Measurements by Geodetic Methods. FIG Commission 6 (Ed.):

Krakow, 22.-24.09.1975. Proceedings

Kuang, S. (1993): A Methodology for the Accuracy Analysis

of the Finite Element Computations Applied to Structural Deformation

Studies. Allgemeine Vermessungsnachrichten, International Edition,

vol. 10, pp. 1-14

Kuhlmann, H. (1996): Ein Beitrag zur Überwachung von

Brückenbauwerken mit kontinuierlich registrierten Messungen.

Wissenschaftliche Arbeiten der Fachrichtung Vermessungswesen der Universität

Hannover, No. 218

Lu, G. (1987): On the Separability of Deformation Models.

Zeitschrift für Vermessungswesen 112, pp. 555-563

Natke, H.G. (1983): Einführung in Theorie und Praxis

der Zeitreihen- und Modalanalyse. Vieweg und Sohn,

Braunschweig-Wiesbaden

Pelzer, H. (1971): Zur Analyse geodätischer

Deformationsmessungen. Deutsche Geodätische Kommission, Reihe C, No.

164, München

Pelzer, H. (1977a): Zur Analyse von permanent

registrierten Deformationen. VII. Internationaler Kurs für

Ingenieurvermessungen hoher Präzision, Technische Hochschule Darmstadt,

29.09.-08.10.1976. Proceedings, pp. 781-796

Pelzer, H. (1977b): Ein Modell zur meßtechnischen und

mathematischen Erfassung kontinuierlicher Deformationsvorgänge. XV.

FIG-Congress, Stockholm 1977. Proceedings, paper 607.1

Pelzer, H. (1978): Geodätische Überwachung dynamischer

Systeme I. 2nd International Symposium on Deformation

Measurements. Bonn, 25.-28.09.1978. Hallermann, L. (ed.):

Vermessungswesen, Band 6, paper 60. K. Wittwer, Stuttgart

Pelzer, H. 1987: Deformationsuntersuchungen auf der Basis

kinematischer Modelle. Allgemeine Vermessungs-Nachrichten 94, pp.

49-62

Pfeufer, A. (1990): Beitrag zur Identifikation und

Modellierung dynamischer Deformationsprozesse. Vermessungstechnik 38,

pp. 19-22

Pfeufer, A. (1993): Analyse und Interpretation von

Überwachungsmessungen - Terminologie und Klassifikation. Zeitschrift für

Vermessungswesen 118, pp. 470-476

SFB 477 (2000): Collaborative Research Center: Life Cycle

Assessment of Structures via Innovative Monitoring. Technical University of

Brunswick.

http://www.sfb477.tu-bs.de

Szostak-Chrzanowski, A., A. Chrzanowski, Y.Q. Chen

(1994): Error Propagation in the Finite Element Analysis of Deformations.

XX. FIG Congress, Melbourne 1994. Proceedings, paper 602.4

Teskey, W.F. (1986): Integrated Analysis of

Deformations. Open File Report to the Department of Surveying

Engineering, University of Calgary, Alberta, Canada

Teskey, W.F. (1988): Integrierte Analyse geodätischer

und geotechnischer Daten sowie physikalischer Modelldaten zur Beschreibung

des Deformationsverhaltens großer Erddämme unter statischer Belastung.

Deutsche Geodätische Kommission, Reihe C, No. 341, München

Welsch, W. (1996): Geodetic Analysis of Dynamic

Processes: Classification and Terminology. 8th International

FIG-Symposium on Deformation Measurements, Hong Kong, 25.-28.06.1996.

Proceedings,

pp. 147-156

Welsch, W., O. Heunecke (1999): Terminology and

Classification of Deformation Models. 9th International

FIG-Symposium on Deformation Measurements, Olsztyn, 27.-30.09.1999.

Proceedings,

pp. 416-429

Welsch, W., O. Heunecke, H. Kuhlmann (2000):

Auswertung geodätischer Überwachungsmessungen, 510 pp. Wichmann Verlag,

Heidelberg

Wernstedt, J. (1989): Experimentelle Prozeßanalyse.

R. Oldenbourg Verlag, München-Wien

|

(6)

(6)